When making a commercial workspace, industrial machine lights are very frequently among the last elements considered. Until lately, most builders did not think beyond overall levels in workspaces and just provided overhead lighting for ambient light. However, anybody that has ever labored with industrial machines, including lathes, drills, presses and mills, recognizes that each one has specialized illumination needs. The best industrial lighting can increase productivity and reduce worker injuries inside a shop. Selecting the very best machine means considering numerous practical factors. Whether you’ll need a drill light, a press, a lathe or perhaps a mill, fundamental essentials things you ought to be considering.

Task Lighting Reduces Energy Costs and Increases Worker Productivity

Factories that depend on general lighting to supply enough light for detailed tasks and industrial tasks see high energy costs minimizing worker productivity. It is better to make use of task by means of industrial machine lighting. It cuts down on the requirement for better general lights and directs illumination wherever the staff member needs so that it is.

Machine Light Position

With regards to illuminating the job surface, the position of the machine light an important factor. It must be placed in order that it shines around the work surface and casts minimal shadows that hinder vision. When picking out the positioning for any drill light, lathe or any other industrial machine, there’s a couple of questions you should ask.

How can the sunshine be mounted? Industrial lighting could be installed on the device or from the machine. Machine-mounted frequently provide optimal lighting for tasks because they may be positioned nearer to the job surface. Industrial machine lighting solutions include magnetic mounts, clamp mounts plus they that may be attached to machines using bolts.

If the light be fixed or adjustable? In some instances, a set light is going to be sufficient for lighting the job surface. In other people, however, a piece of equipment light on the flexible arm or having a pivoting mind may well be a better option.

Machine Light Construction

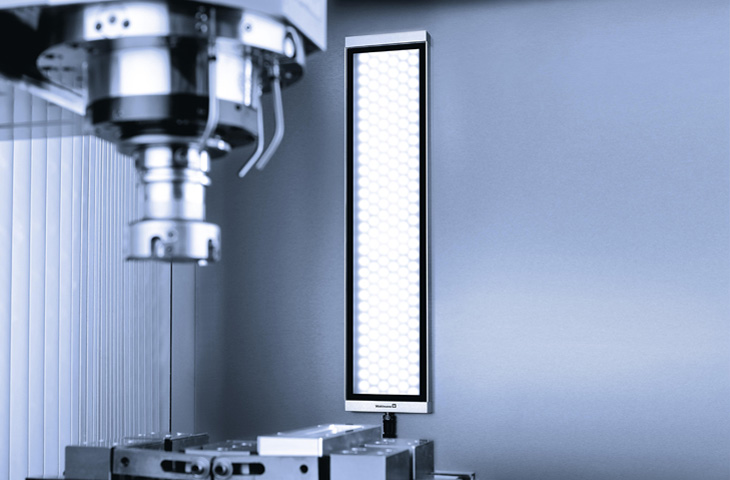

It’s obvious that machine mounted industrial lighting should be sturdier kinds of lights due to the ecological conditions. Search for machine light choices with sturdy, heavy-duty housing and lightweight bulbs that may withstand the continual vibration from the machine being used.

The DUR-A-LITE was created particularly to satisfy the rigorous requirements of a piece of equipment light. The illuminating tube is enclosed within an outer tube that protects the bulb from contaminants in addition to protecting the staff member from breaking glass when the bulb should break. The housing and construction are particularly designed to cope with strong vibrations that many incandescent and fluorescent lights can’t tolerate.